TCM-A/TCM-B SERIES ISIKHOKELO ROD TCHINA ALUMINIUM IALLOY TUBE

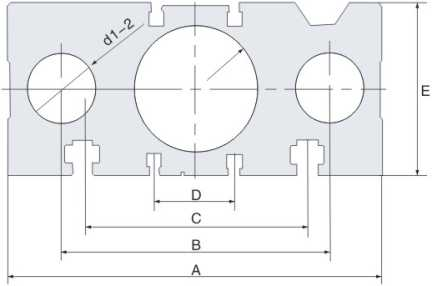

I-TCM-A (φ12-80) Uthotho lwe-Cylinder Tube

| No | d | d1-2 | A | B | C | D | E |

| 1 | φ12 | φ10 | 58 | 41 | 37 | 9 | 26 |

| 2 | φ16 | φ12.5 | 64 | 46 | 38 | 10.5 | 30 |

| 3 | φ20 | φ14.5 | 83 | 54 | 44 | 12.5 | 36 |

| 4 | φ25 | φ18 | 93 | 64 | 50 | 15 | 42 |

| 5 | φ32 | φ22.5 | 112 | 78 | 63 | 19.5 | 48 |

| 6 | φ40 | φ22.5 | 120 | 86 | 72 | 25 | 54 |

| 7 | φ50 | φ27.5 | 148 | 110 | 92 | 33 | 64 |

| 8 | φ63 | φ27.5 | 162 | 124 | 110 | 34 | 78 |

| g | φ80 | φ34 | 202 | 156 | 140 | 48 | 91.5 |

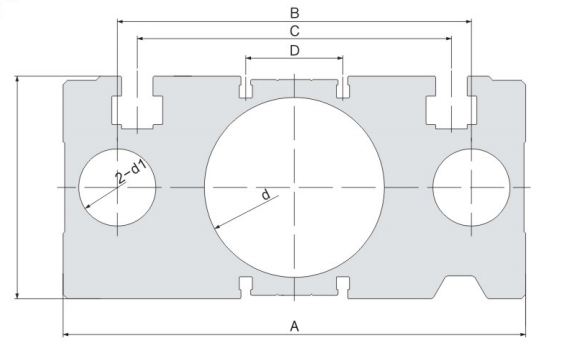

I-TCM-B (φ12-63) Uthotho lwe-Cylinder Tube

| NO | d | 2-d1 | A | B | C | D | E |

| 1 | φ12 | φ10 | 58 | 41 | 37 | 9 | 26 |

| 2 | φ16 | φ13 | 64 | 46 | 38 | 10.5 | 30 |

| 3 | φ20 | φ17 | 83 | 54 | 44 | 12.5 | 36 |

| 4 | φ25 | φ18 | 93 | 64 | 50 | 15 | 42 |

| 5 | φ32 | φ22.5 | 112 | 78 | 63 | 19.5 | 48 |

| 6 | φ40 | φ22.5 | 120 | 86 | 72 | 25 | 54 |

| 7 | φ50 | φ27 | 148 | 110 | 92 | 33 | 64 |

| 8 | φ63 | φ27 | 162 | 124 | 110 | 34 | 78 |

Izinto eziphathekayo zeAluminiyam ingxubevange yeProfayili I-Aluminiyam ye-pneumatic cylinder ityhubhu: i-aluminium ingxubevange ye-6063 T5

Ubude bethu obuqhelekileyo bungama-2000mm, ukuba ufuna obunye ubude, nceda ngokukhululekileyo usazise.

Umphezulu we-Anodized: Ityhubhu yangaphakathi-15±5μm Ityhubhu yangaphandle-10±5μm

Izivumelwano zokuyila i-FESTO, i-SMC, i-Airtac, i-Chelic njl.

Izivumelwano kumgangatho we-ISO 6430 ISO6431 VDMA 24562 ISO15552 njl.

Isetyenziselwa i-cylinder eqhelekileyo, i-compact cylinder, i-mini cylinder, i-Dual Rod cylinder, i-Slide cylinder, i-Slide Table cylinder, i-Gripper njl njl. Kwakhona kwiisilinda ezikhethekileyo.

Ukuqulunqwa kwemichiza:

| Ukuqulunqwa kwemichiza | Mg | Si | Fe | Cu | Mn | Cr | Zn | Ti |

| 0.81 | 0.41 | 0.23 | <0.08 | <0.08 | <0.04 | <0.02 | <0.05 |

Inkcazo:

| Ukuqina koxinzelelo (N/mm2) | Ukomelela kweSivuno (N/mm2) | I-Ductility (%) | Ukuqina komphezulu | Ukuchaneka kweDayimitha yangaphakathi | Uburhabaxa baNgaphakathi | Ukuthe tye | Impazamo yokutyeba |

| Sb 157 | S 0.2 108 | S8 | HV 300 | H9-H11 | < 0.6 | 1/1000 | ± 1% |

Ukunyamezela kweThubhu yeAluminiyam yeAluminiyam:

| UKUNYANZELWA KWE-ALUMINIUM ALLOY TUBE | ||||||

| Ubungakanani Bore | UNYAMEZELO | |||||

| mm | H9(mm) | H10(mm) | H11(mm) | |||

| 16 | 0.043 | 0.07 | 0.11 | |||

| 20 | 0.052 | 0.084 | 0.13 | |||

| 25 | 0.052 | 0.084 | 0.13 | |||

| 32 | 0.062 | 0.1 | 0.16 | |||

| 40 | 0.062 | 0.1 | 0.16 | |||

| 50 | 0.062 | 0.1 | 0.16 | |||

| 63 | 0.074 | 0.12 | 0.19 | |||

| 70 | 0.074 | 0.12 | 0.19 | |||

| 80 | 0.074 | 0.12 | 0.19 | |||

| 100 | 0.087 | 0.14 | 0.22 | |||

| 125 | 0.1 | 0.16 | 0.25 | |||

| 160 | 0.1 | 0.16 | 0.25 | |||

| 200 | 0.115 | 0.185 | 0.29 | |||

| 250 | 0.115 | 0.185 | 0.29 | |||

| 320 | 0.14 | 0.23 | 0.36 | |||

FAQ:

I-Q1: Yintoni imodeli ye-TCM?

A: Uphawu lwemveliso

1. Umgangatho we-JIS uphunyeziwe

2. Izikhokelo ezimbini zetsimbi ezikhethekileyo zentsimbi kunye nomgca womgca okanye isikhokelo sobhedu sisetyenziselwa ukuthintela ukujikeleza.Bayakwazi ukuthwala i-torque ephezulu kunye nomthwalo we-radial.

3. Iyunithi yokuqhuba kunye neyunithi yesikhokelo kwi-barrel efanayo ukuba akukho zixhobo ezongezelelweyo ezifunekayo kunye nesithuba esincinci esifunekayo Ukungena komoya kukhetho kwaye kulungele ukuyifaka.

4. I-bottom, i-back side kunye ne-plate yokulungisa yomzimba oyintloko ngokulandelanayo ineendlela ezimbini zokuqhelanisa ngokuthe ngqo (Jonga i-PA orifice kunye ne-orifice kwi-XX point), enokubonelela ngokufakela i-orientation ngokuchaneka okuphezulu kwimeko ekhethekileyo.

5. Ukhetho lokuxhoma ukutshintshela kunye nokubonelela ngeendawo zokubeka ezi-4.

6. Uyilo olukhethekileyo lomzimba oyintloko lubonelela ngeentaba ezininzi;

I-Q2: Ukuba sithenga i-TCM, ngaba kunokwenzeka nge-anodizing ye-Aluminium Air Cylinder Tubes?

A: Le Cylinder ye-Pneumatic ayikhuthazwa ukuba i-oxidized, kuba umthengi kufuneka ayinqumle ngokwakhe kwaye ayiqhube kwaye enze unyango lwe-oksijini emva kokuyithenga.

I-Q3: Yintoni ubude ukuba siyalela i-Pneumatic Cylinder Tube Pipe?

A:Ubude ziimitha ezi-2.

Q4: Wumnqwazilixesha lokuhambisamalunga Iprofayile yeAluminiyam yeSilinda yoMoya?

A: ☆ Ukuba iityhubhu ezenziwe ngokwezifiso, ixesha lifuna iintsuku zokusebenza ezingama-50-60, kodwa ukuba kwiityhubhu eziqhelekileyo, ixesha lethu lokuhambisa liyi-15-20 iintsuku zokusebenza.