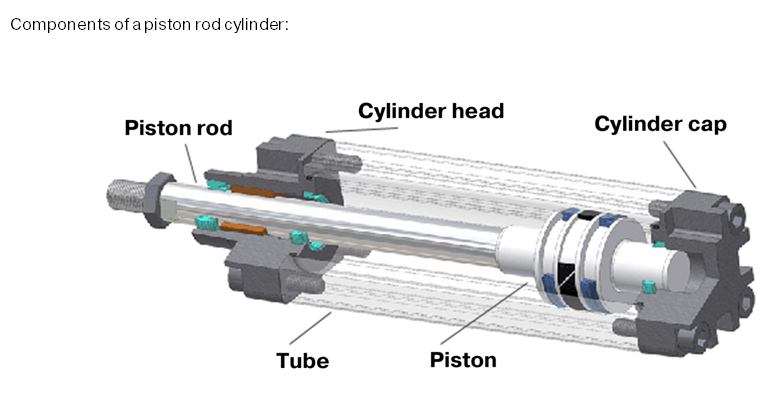

Iisilinda ze-pneumatic (ezenziwe ngetyhubhu ye-pneumatic cylinder, i-piston rod, i-cylinder cap), ekwabizwa ngokuba yi-cylinders yomoya, i-pneumatic actuators, okanye i-pneumatic drives, zizixhobo ezilula zoomatshini ezisebenzisa amandla omoya ocinezelweyo kwaye ziwujike ube yintshukumo yomgca.Ukugcinwa okulula kunye nokugcinwa okuphantsi, iisilinda ze-pneumatic zisebenza ngokubanzi ngesantya esisezantsi kunye namandla angaphantsi kunezombane ze-hydraulic okanye zombane, kodwa ziyindlela ecocekileyo kunye neyonga imali yokunyakaza okuthembekileyo kwiindawo ezininzi zoshishino.Uyilo oluqhelekileyo lubandakanya i-cylinder okanye ityhubhu etywinwe kuzo zombini iziphelo, kunye ne-cap kwelinye icala kunye nentloko kwelinye icala.I-cylinder iqulethe ipiston, efakwe kwintonga.Intonga ihamba kwaye iphuma kwelinye icala lombhobho, iqhutywe ngumoya oxinzelelweyo.Kukho iindlela ezimbini eziphambili: isenzo esisodwa kunye nesibini.

Uyilo lwesilinda ye-pneumatic:

Kwimibhobho ye-pneumatic esebenza enye, umoya unikezelwa ngezibuko elinye ukuya kwelinye icala lepiston, nto leyo ebangela ukuba intonga yepiston yande kwicala elinye kumsebenzi onjengokuphakamisa into.Elinye icala likhupha umoya kwindalo esingqongileyo.Ukushukuma kwicala elichaseneyo kwenzeka rhoqo ngokusetyenziswa kwemithombo yomatshini, ebuyisela intonga yepiston kwindawo yayo yokuqala okanye yesiseko.Ezinye iisilinda ezibambeleyo zisebenzisa umxhuzulane, ubunzima, intshukumo yomatshini, okanye intwasahlobo enyuswe ngaphandle ukuze inike amandla i-stroke yokubuya, nangona ezi ziyilo zingaxhaphakanga kangako.Ngokwahlukileyo koko, iisilinda ze-pneumatic ezisebenza kabini zibonisa amazibuko amabini abonelela ngomoya ocinezelekileyo ukuba anwebe kwaye arhoxise intonga yepiston.Uyilo olusebenza kabini luqheleke ngakumbi kulo lonke ushishino, kuqikelelwa ukuba i-95% yezicelo zisebenzisa esi simbo sombhobho.Nangona kunjalo, kwizicelo ezithile, i-cylinder-acting single yisisombululo esinendleko kunye nesifanelekileyo.

Kwisilinda ebambeleyo enye, uyilo lunokuba "kwindawo yesiseko thabatha" kunye nokubuya kwentwasahlobo, okanye "indawo yesiseko kunye" kunye nokwandiswa kwentwasahlobo.Oku kuxhomekeke ekubeni umoya ocinezelweyo usetyenziselwa ukunika amandla i-out-stroke okanye i-in-stroke.Enye indlela yokucinga ngezi zimbini iinketho kukutyhala kunye nokutsala.Kuyilo lokutyhala, uxinzelelo lomoya ludala ukutyhala, okutyhala ipiston.Ngoyilo lokutsala, uxinzelelo lomoya luvelisa i-thrust etsala ipiston.Olona hlobo lucaciswe kakhulu luxinzelelo olwandisiweyo, olusebenzisa intwasahlobo yangaphakathi ukubuyisela ipiston kwindawo yayo yesiseko xa umoya uphuma.Enye inzuzo yoyilo olubambeleyo kukuba xa kunokwenzeka ukuba amandla okanye ilahleko yoxinzelelo, ipiston ibuyele ngokuzenzekelayo kwindawo yayo esisiseko.Isithintelo solu hlobo kukungangqinelani kwamandla okukhutshwa ngexesha lokubethwa ngokupheleleyo ngenxa yamandla entwasahlobo achaseneyo.Ubude be-stroke bukwathintelwe sisithuba esifunwa yintlakohlaza ecinezelweyo, kwakunye nobude obukhoyo basentlakohlaza.

Kwakhona khumbula ukuba ngeesilinda ezibambeleyo enye, umsebenzi othile ulahlekile ngenxa yamandla entwasahlobo achaseneyo.Oku kuncitshiswa kwamandla kufuneka kuthathelwe ingqalelo xa ulinganisa olu hlobo lwesilinda.I-diameter kunye ne-stroke zezona zinto zibalulekileyo ekufuneka ziqwalaselwe ngexesha lokubala ubukhulu.Idayamitha ibhekisa kwidayamitha yepiston, echaza amandla ayo xa kuthelekiswa noxinzelelo lomoya.I-cylinder diameters ekhoyo ichazwa luhlobo lwe-cylinder kunye ne-ISO okanye eminye imigangatho.I-Stroke ichaza ukuba zingaphi iimilimitha ezinokuhamba ipiston kunye nepiston.Umgaqo jikelele kukuba ubukhulu be-cylinder bore, imveliso enkulu yamandla.Iisayizi ze-cylinder bore eziqhelekileyo ziphakathi kwe-8 ukuya kwi-320 mm.

Ingqwalasela yokugqibela sisimbo sokunyuka.Ngokuxhomekeke kumenzi, ulungelelwaniso oluninzi lukhoyo.Ezinye zezona zixhaphakileyo ziquka ukunyuswa kweenyawo, ukunyuswa komsila, intaba ye-pivot yangasemva, kunye nentaba ye-trunnion.Olona khetho lungcono luya kumiselwa sisicelo esithile kunye namanye amacandelo enkqubo.

Ixesha lokuposa: Aug-19-2022